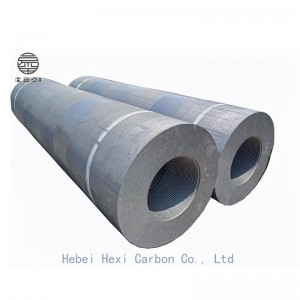

400 UHP graphite lantarki

Ana amfani da na'urorin lantarki na graphite musamman a aikin ƙera ƙarfe. Ƙarfe yana narkewa a cikin tanderun baka na lantarki kuma ana sake yin fa'ida. A matsayin nau'in jagora, su ne muhimmin sashi a cikin irin wannan

UHP graphite lantarki ne yafi sanya sama da high quality-coke allura, kuma yadu amfani a matsananci high ikon wutar lantarki baka tanderu.It ne iya ɗaukar halin yanzu yawa fiye da 25A/cm2

| Kwatanta Bayanin Fasaha don UHP Graphite Electrode 16" | ||

| Electrode | ||

| Abu | Naúrar | Specific mai bayarwa |

| Halayen Halayen Sanda | ||

| Diamita na Ƙa'ida | mm | 400 |

| Max Diamita | mm | 409 |

| Min Diamita | mm | 403 |

| Tsawon Suna | mm | 1600/1800 |

| Matsakaicin Tsayin | mm | 1700/1900 |

| Min Tsawon | mm | 1500/1700 |

| Yawan yawa | g/cm3 | 1.68-1.73 |

| Ƙarfin mai juzu'i | MPa | ≥ 12.0 |

| Young' Modul | GPA | ≤13.0 |

| Takamaiman Juriya | µΩm | 4.8-5.8 |

| Matsakaicin yawa na yanzu | KA/cm2 | 16-24 |

| Ƙarfin ɗauka na Yanzu | A | 25000-40000 |

| (CTE) | 10-6 ℃ | ≤1.2 |

| abun cikin toka | % | ≤0.2 |

| Halayen Halayen Nono (4TPI) | ||

| Yawan yawa | g/cm3 | 1.78-1.84 |

| Ƙarfin mai juzu'i | MPa | ≥22.0 |

| Young' Modul | GPA | ≤18.0 |

| Takamaiman Juriya | µΩm | 3.4 zuwa 4.0 |

| (CTE) | 10-6 ℃ | ≤1.0 |

| abun cikin toka | % | ≤0.2 |

Tsarin sarrafawa

Graphite electrode ne yafi sanya na man fetur coke da allura coke, gauraye da kwal farar, samun ta hanyoyin da calcinations, kneading, forming, yin burodi, graphitizing da machining, a karshe ya zama samfurori. Anan akwai wasu bayanai don wasu tsarin samarwa:

Kneading: Yin motsawa da haɗuwa da wani adadin ƙwayar carbon da foda tare da wani adadin abin ɗaure a wani yanayin zafi, wannan tsari shine ake kira kneading.

Ayyukan durkushewa

① Mix kowane irin albarkatun kasa a ko'ina, kuma a lokaci guda yi m carbon kayan daban-daban barbashi masu girma dabam uniformly Mix da cika, da kuma inganta yawa daga cikin cakuda;

②Bayan ƙara kwalta kwal, sai a haɗa duk kayan da kyau tare.

③Wasu filayen kwal suna shiga cikin ɓangarorin ciki, wanda ke ƙara haɓaka ɗimbin yawa da mannewa na manna.

Ƙirƙirar: Manna carbon ɗin da aka kneaded ana fitar da shi cikin koren jiki (ko samfurin kore) tare da takamaiman siffa, girman, yawa da ƙarfi a cikin kayan gyare-gyare. Manna yana da nakasar filastik a ƙarƙashin ƙarfin waje.

Roasting kuma ake kira baking, Yana da babban zafin jiki magani, yin kwal farar carbonized zuwa coke kafa, wanda karfafa carbonaceous aggregates da foda barbashi tare da high inji ƙarfi, m resistivity, mafi thermal kwanciyar hankali da sinadaran kwanciyar hankali.

Gasasshen na biyu shine a sake yin gasa sau ɗaya, yana mai da ratsawar farar carbonized. Electrodes (duk nau'ikan banda RP) da nonuwa masu buƙatar girma mai yawa ana buƙatar a gasa su na biyu, da nonuwa a tsoma uku a gasa huɗu ko biyu tsoma uku.